Wi-Tronix Internship

Summer 2025 | Bolingbrook, IL

Skills: Rail Technology, SOLIDWORKS, Injection Mold Design, Sheet Metal Design, Technical Drawings, Presentation, SAFe®

Core Values: Customer Focused Outcomes, Excellence, Ownership, Innovation, Teamwork, and Make Things Happen

Skills: Injection Mold Design

A Class I Railroad expressed a need for a device which would ensure complete and secure connections between 3.5mm jack cables on their locomotives. I was assigned to ideate, prototype, and prepare a solution to be manufactured for the customer by the end of the summer. I completed the prototyping phase within a couple weeks through heavy use of FDM 3D printing, and then my design was released for feedback to the railroad and other departments at Wi-Tronix. After incorporating the relevant feedback and double-checking design constraints, higher resolution SLS prototypes were ordered to fully validate the design. Then, once I presented my finalized design and prototypes to the relevant parties, work towards manufacturing began. I was responsible for preparing the quote as well as ensuring DFM constraints were satisfied, and once those duties were completed, my work was handed off to the purchasing team to release the parts for manufacture.

Note: The products pictured are merely visual aids to describe my work, and are not representative of the work I completed

Audio Jack Retention Device

Skills: Sheet Metal Design

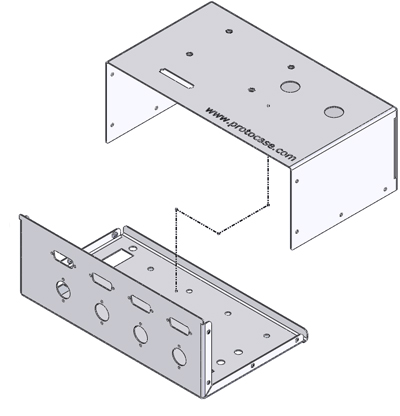

During my time at Wi-Tronix, work on a new product was underway, and fortunately I got to play a direct role in preparing the systems needed for final release.

In particular, the production floor needed a small computer to test each unit after assembly, and I was tasked with souring an enclosure for this device. This encompassed everything from researching preexisting solutions, to quoting custom solutions, and eventually creating a custom enclosure using the SOLIDWORKS sheet metal design suite.

I began prototyping first using foam-core to validate measurements, before then creating a functional 3D printed proof of concept. The final step was, again, preparing quotes and ensuring all DFM constraints were satisfied, and then the project was handed off to purchasing for final release of the order.

Note: The products pictured are merely visual aids to describe my work, and are not representative of the work I completed

Unit Test Device Enclosure

GEMBA is a Japanese word that means “Go to where the work is done,” and this concept is very important at Wi-Tronix. This means that even the interns get to go on tours of Class I Railroad facilities and tag along on trips to install Wi-Tronix products on locomotives.

However, GEMBA does not only happen on locomotives, but it can be as simple as a trip to the production floor. For me, I got to build a Violet (the core product Wi-Tronix offers), and though this may be the least extravagant of my GEMBA trips, it had the most impact. Getting to see how my own engineering drawings and diagrams were getting used on the production floor and seeing how all the parts actually fit together in real life gave me a new appreciation for the work I was doing, which unlocked a new level of intrinsic motivation for the work I was doing.