ILLINI SOLAR CAR

Involvement: Melec Subteam Secondary Lead, Structures Subteam, Mechanical Team

Skills: Seimens NX, Ansys FEA, Rapid Prototyping, Leadership, Collaboration

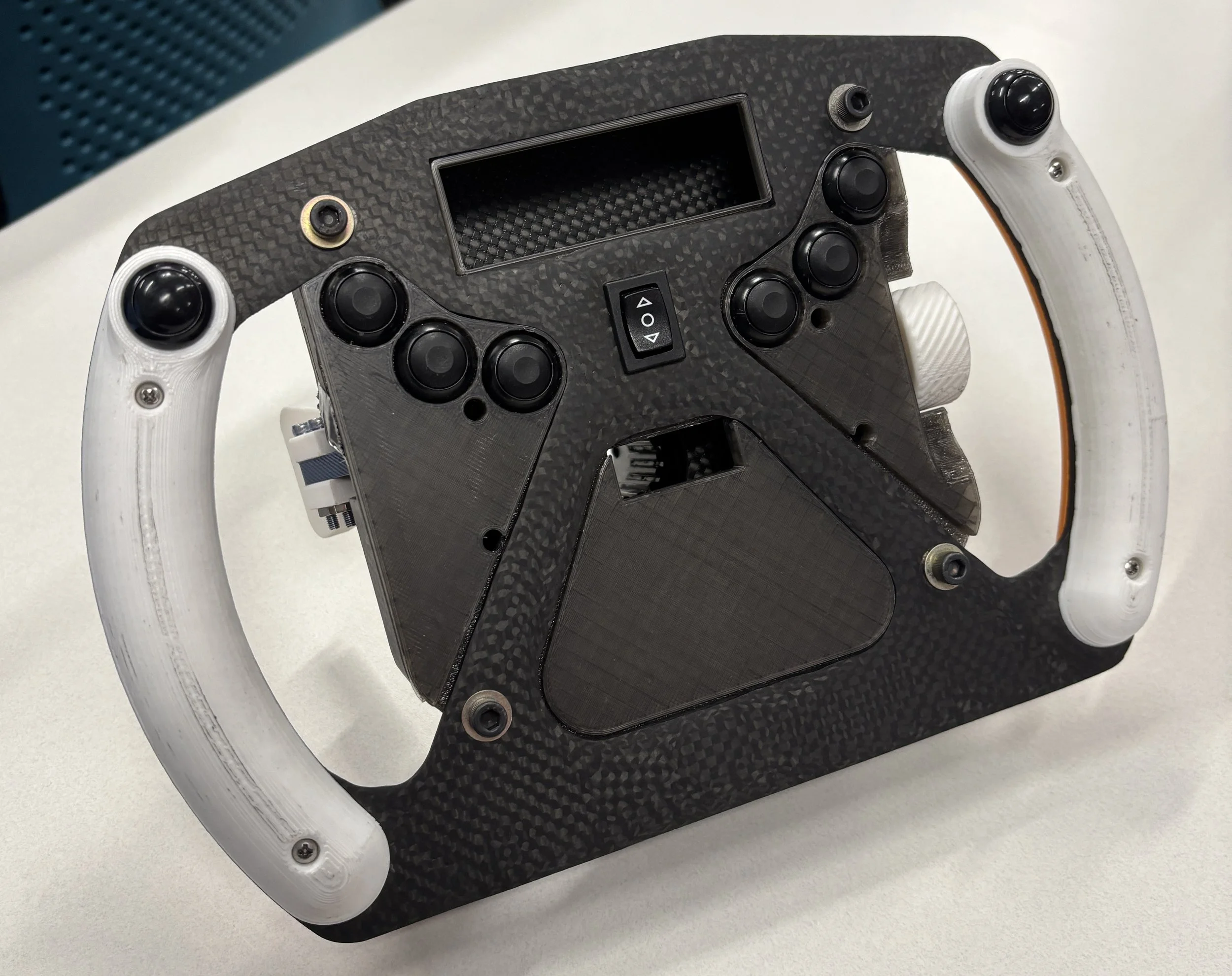

Calypso Steering Wheel

Steering Wheel Enclosure for our 3rd Generation Solar Car

Problem

My teammate and I were assigned to reimagine the steering wheel design for Calypso’s second race.

Main areas for improvement included a renovated braking control scheme and improved design for assembly.

Ideation

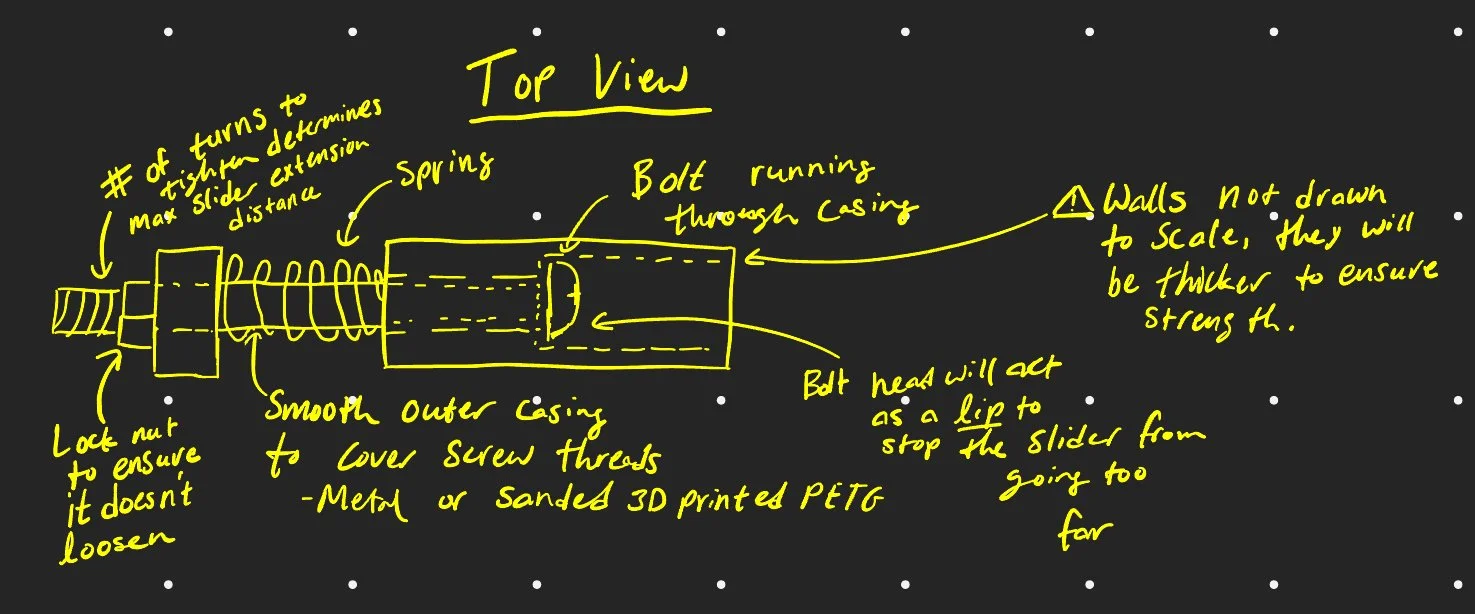

Ideas ranged from simple mechanisms to hold parts in place during assembly to crazy brainstorms for how to create an effective and ergonomic braking control system. Ideas for braking control ranged from XBox controller style triggers all the way to race car paddle shifter levers.

Prototyping

Design Decisions

The braking control paddle was the first area I focused on for improvement. Ergonomics drove decisions for position, length, shape and size, which were refined during prototyping.

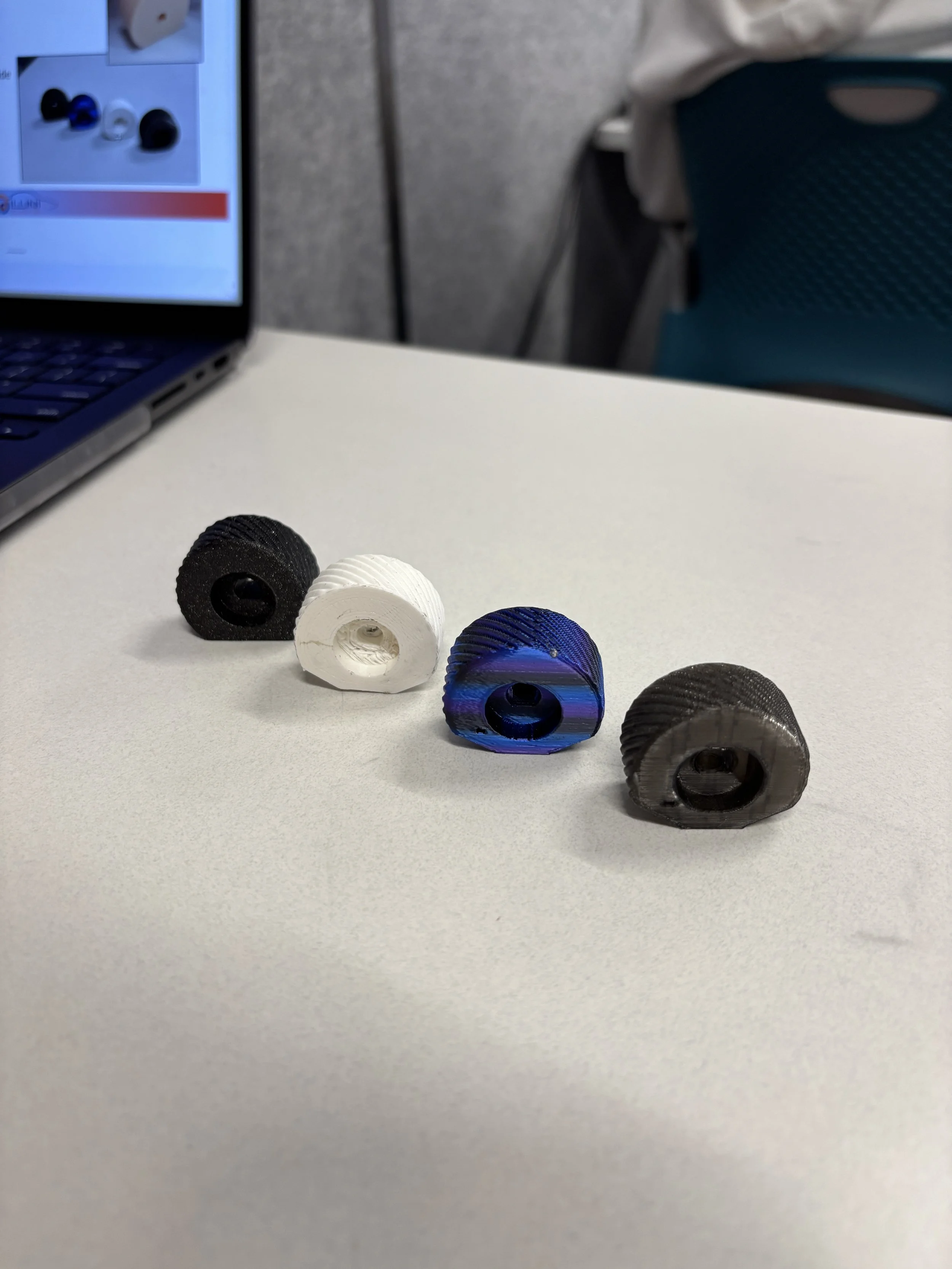

Additionally, I determined that maximizing grip and minimizing assembly complexity of the acceleration control wheel were crucial areas for improvement.

I iterated 9 times on the acceleration control wheel till assembly could be completed independent of other components on the wheel and received positive feedback from drivers.

This stage also allowed me to test fit and finish for electronic components to ensure that the electrical team would be able to install their parts and finish their work efficiently.

Due to this project experiencing few mechanical loads, testing was one of the easier stages of development.

I coordinated with previous drivers and the electrical team to get feedback on ergonomics and verify that all electronic components were easy to install and access.

After completing the build, the team took the wheel to the race this summer and won first place.

Production & Testing

Final Result

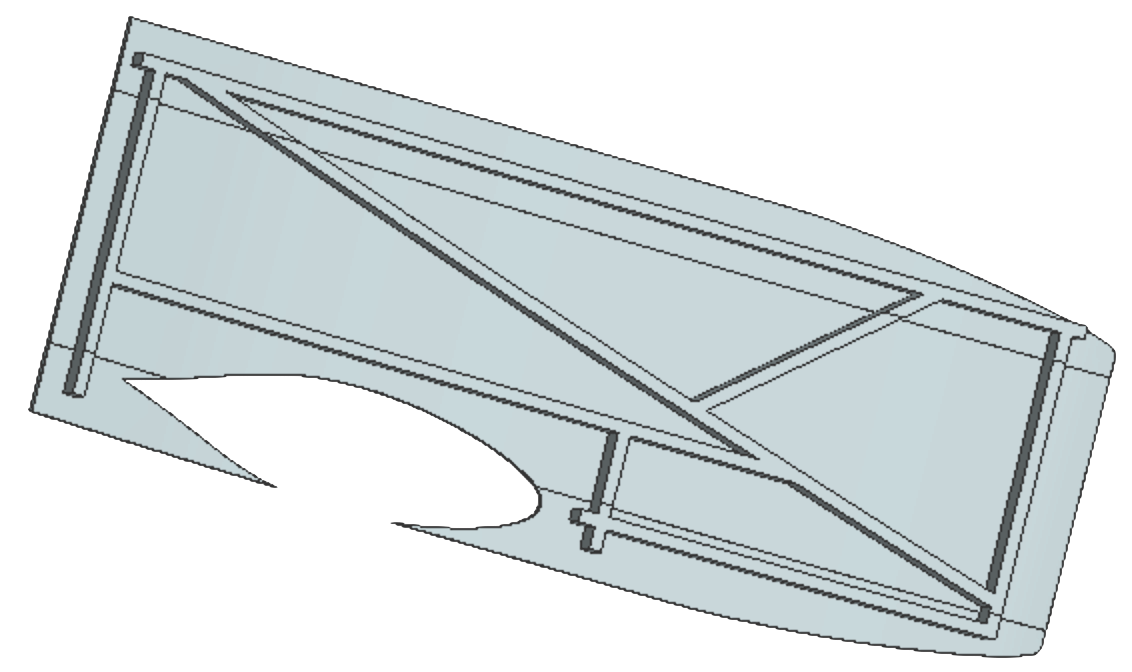

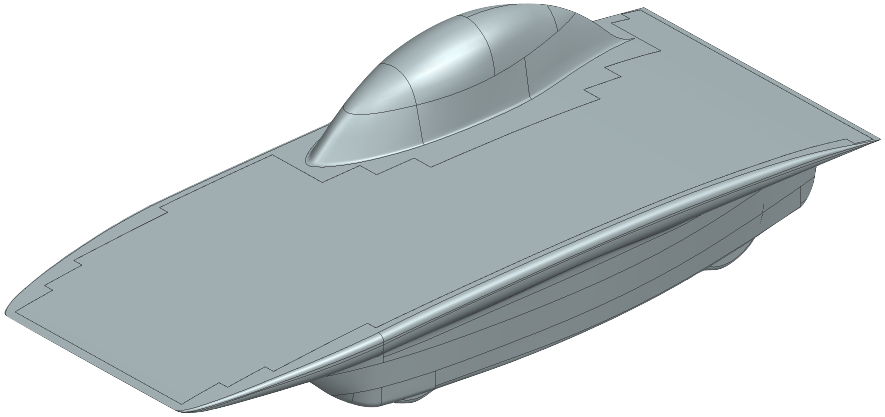

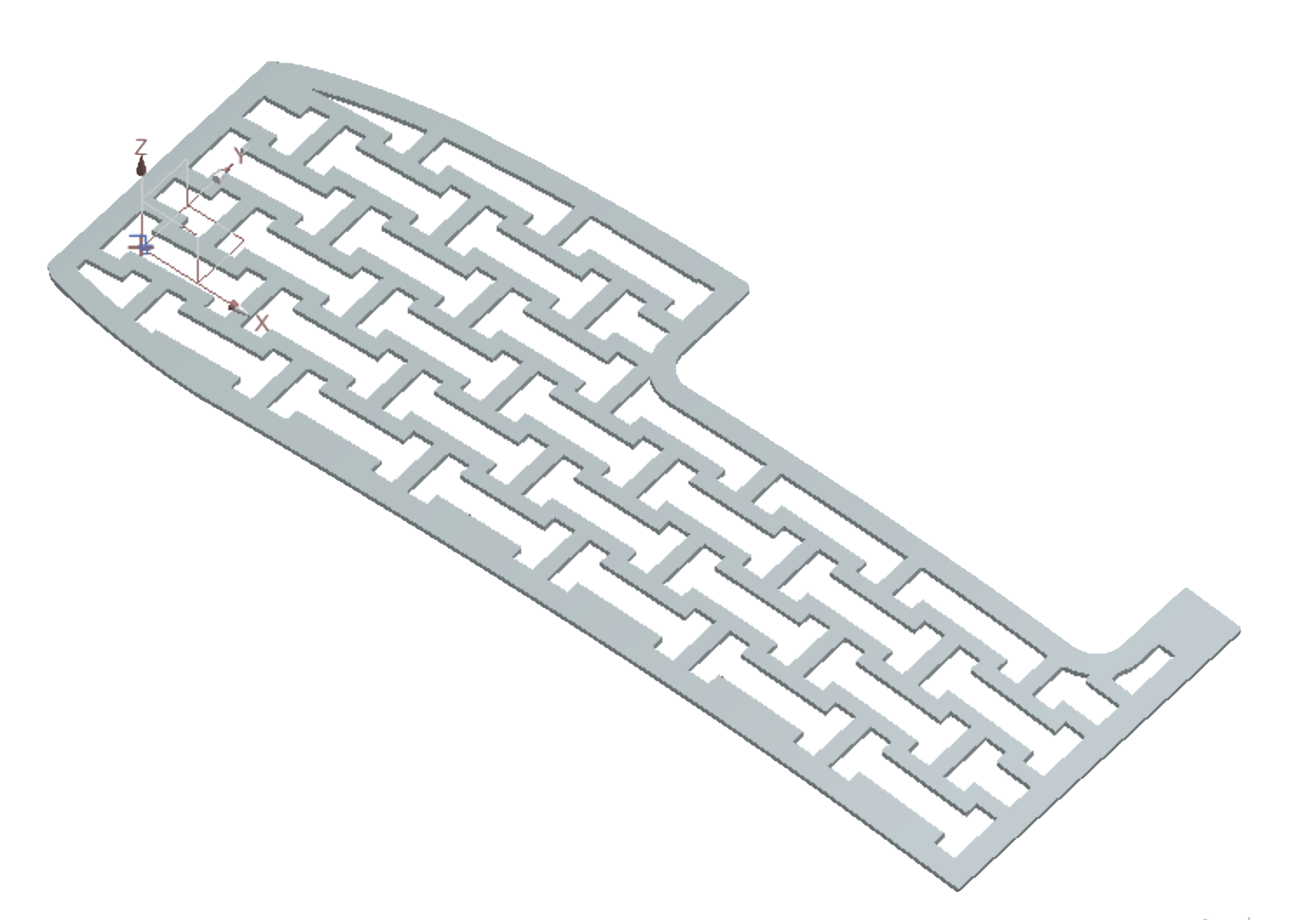

Project D Top Shell Structure

Making optimal aerodynamics a reality using FEA and composite materials

Note: This project is in progress and not yet complete

Problem

Our aero team designed a hyper efficient shape for our car, and it came time to make it a reality — this is where I stepped in. I was tasked with making the theoretical top surface of the car a reality, considering everything from structural stability to manufacturing plans and laying out the array on top.

Research & Development

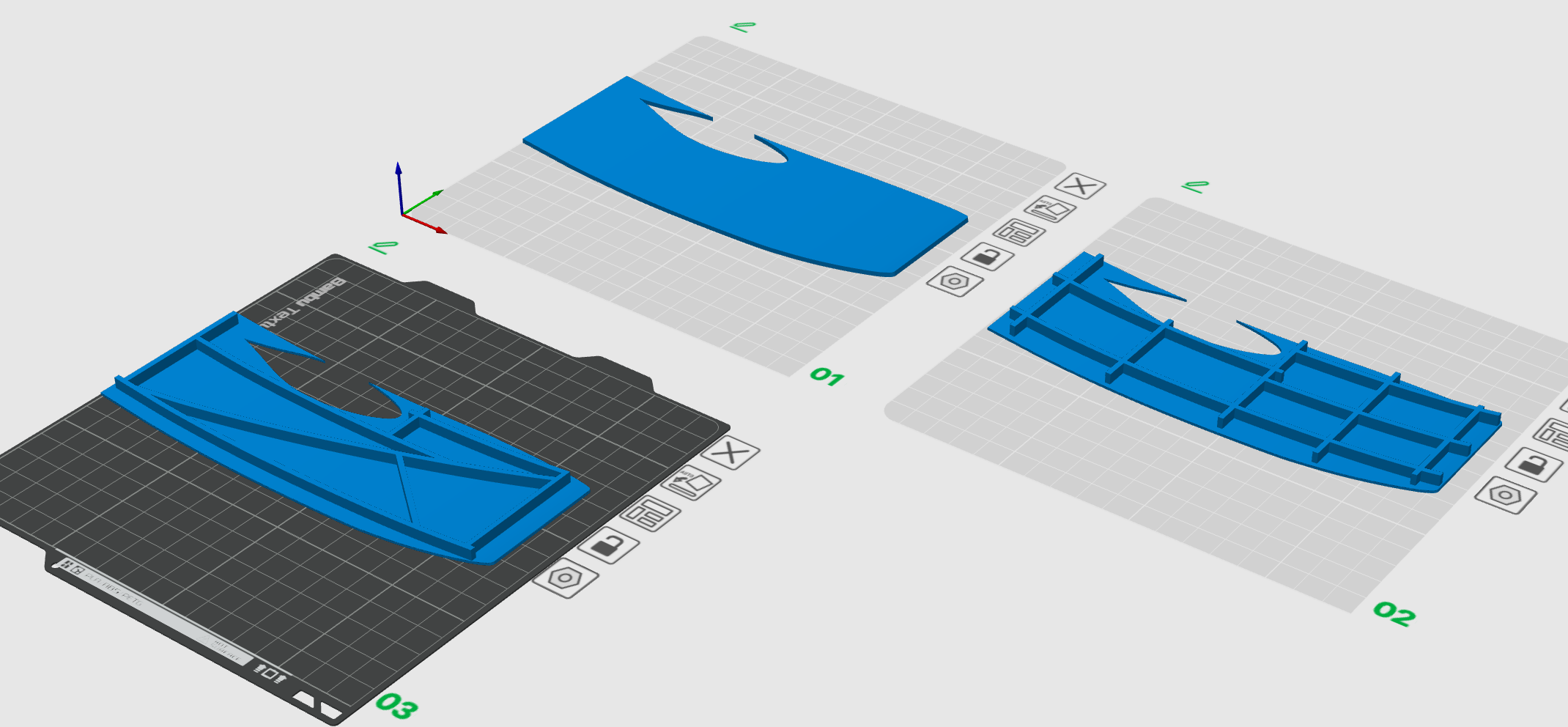

First, to a frame of reference for the rigidity of the initial structure, we 3D printed scale models of a few rudimentary designs.

Then we took these designs to Ansys to get a more solid, yet still very imprecise feel for how different composite schedules will respond to some very simple load cases.

Ideation

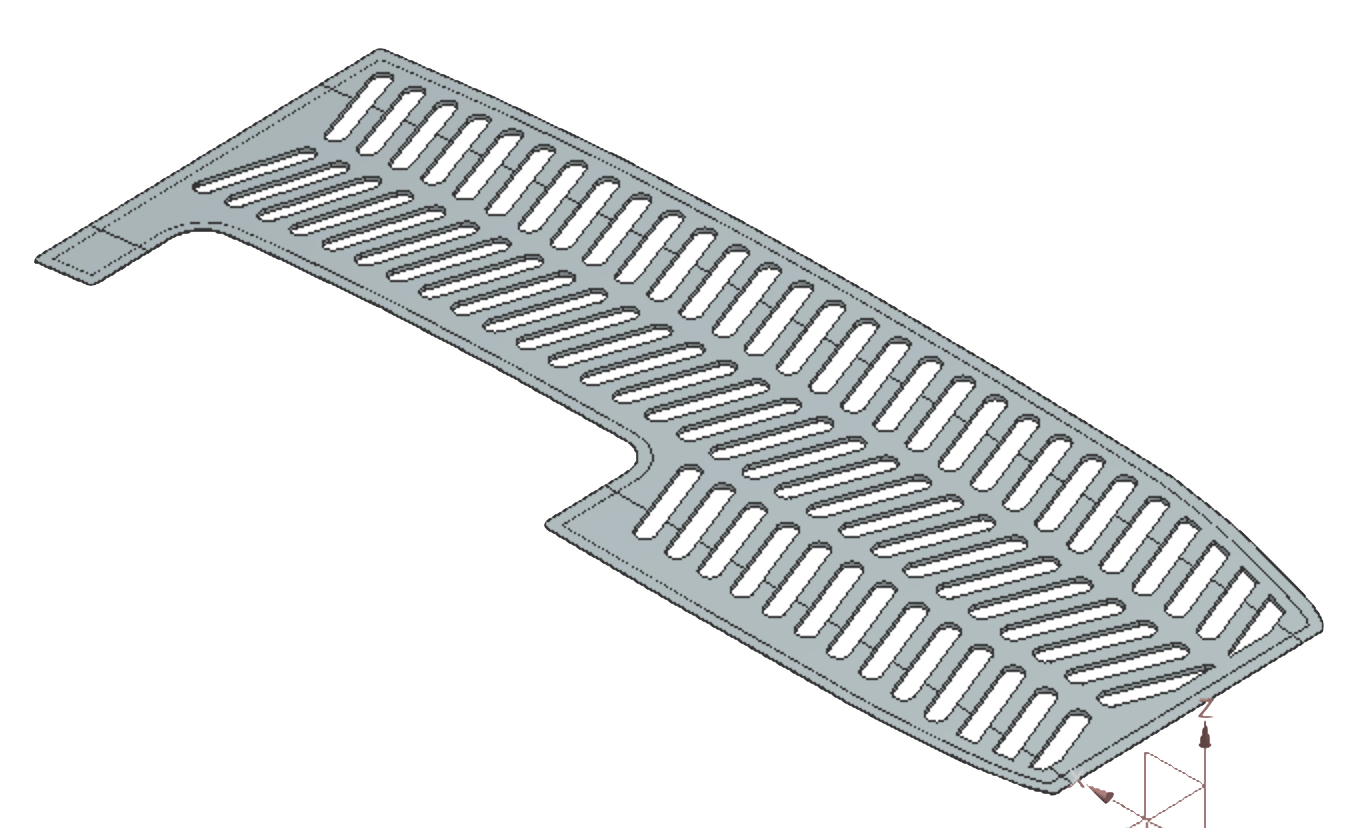

Next was zooming in on smaller problems such as manufacturing light-weighting holes, ensuring proper fit at edge cases, and planning with the electrical team for array compatibility.

Manufacturing

*Current Project Status

This is the current, and most hands-on part of the project.

I worked with the team to prepare our molds for final layups by leading and participating in sanding, puttying and priming work sessions.

I am now working with the electrical side of the array team to make plans for where we need holes and how we can make the top of the car as light as possible.